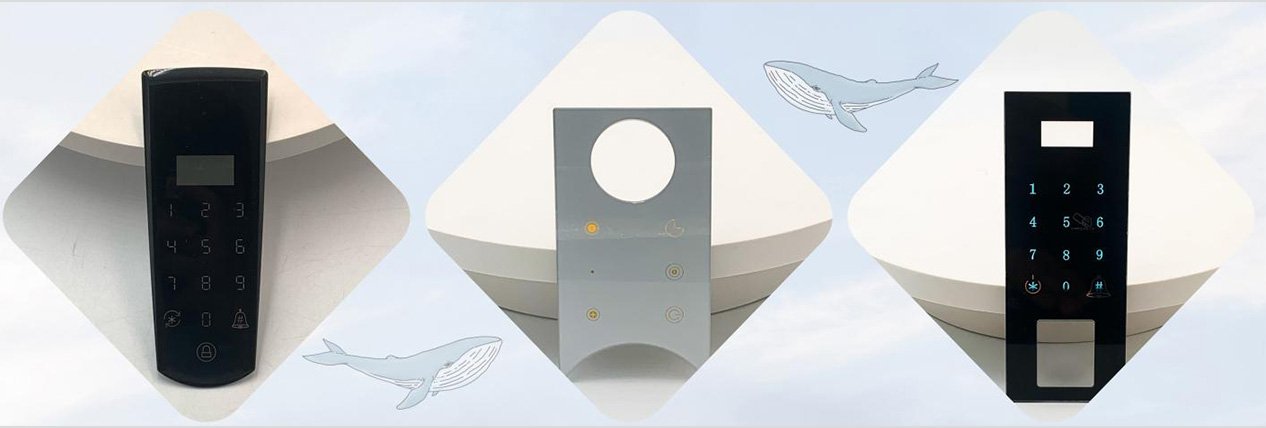

Description of silk screen printed glass

Low temperature screen printing is screen printing after glass tempering, screen printing ink is the use of low temperature ink, ink need to add curing agent, and then drying treatment, Low temperature screen printing is generally used in electronic products.

High temperature screen printing requires a special high temperature ink, glass cutting and grinding processing, and then high temperature screen printing, screen printing after the glass needs to be tempered, making the ink more firm, not easy to fall off. The glass of high temperature screen printing will be tested by paint adhesion testing, and the sharp things will not be scrape glass surface, applied to high-end household appliances.

Advantage of silk screen printing glass panel

1.Can be customized by various patterns customer requested, with multi-colors.

2.High color stability, durable and without color fading.

3.Safety glass with tempered glass desirable properties.

4.Custom patterns and shapes for a wide range of applications.

Features of tempered glass

1. Tempered glass is 5 times harder than ordinary float glass.

2. High security, once tempered glass breakage occurs, the glass disintegrate into small cubical fragments, which are relative harmless to human body.

3. Tempered glass is with Excellent mechanical strength and safety performance .

4. Sizes of tempered glass are produced per your request, once tempered, cannot be cut down.