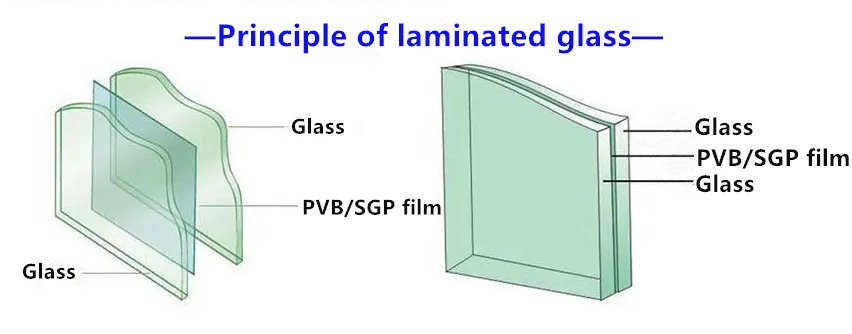

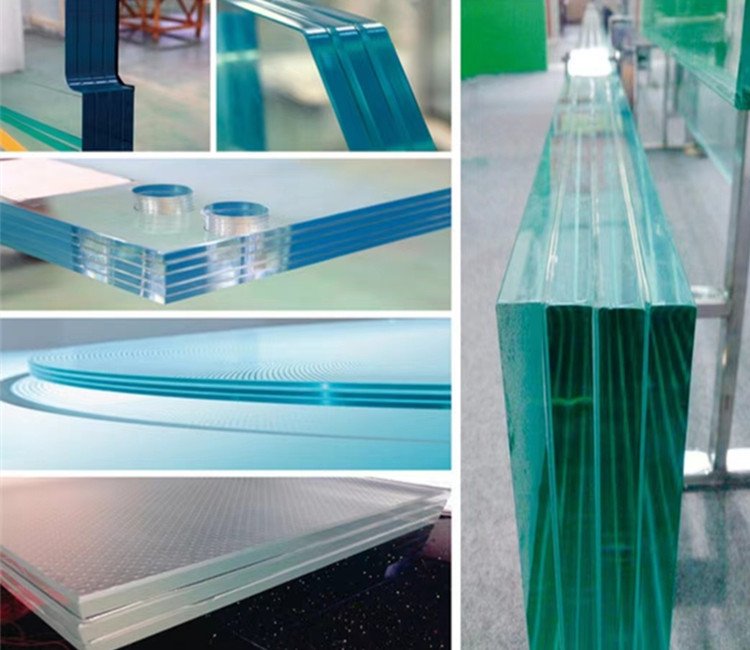

Laminated glass is composed of two or more pieces of glass and organic polymer intermediate film. The intermediate film is placed between two or more pieces of glass, and after high-temperature and high-pressure processing, it is bonded into a whole, forming laminated glass.

When laminated glass is broken, the glass fragments firmly adhere to the intermediate film layer and remain intact, so it is also known as safety glass

Product name | Clear laminated glass |

Glass type | Clear float glass,ultra clear float glass,tinted float glass,etc |

Type of intermediate film layer | PVB film,SGP film,etc |

Film colors | Milky White,Black,French Green,Light Blue,Bronze, Light Grey, Dark Grey, Ocean Blue etc. |

Glass structure | 3+0.38PVB+3mm; 4+0.38PVB+3mm; 5+0.38PVB+5mm; 6+0.38PVB+6mm; 3+0.76PVB+4mm; 4+0.76PVB+4mm; 5+0.76PVB+5mm; 6+0.76PVB+6mm;15+1.52PVB+15mm; 8+1.52PVB+8+1.52PVB+8mm; 10+1.52PVB+10+1.52PVB+10mm,etc |

Size | 100*100mm,300*300mm,500*500mm,1000*1000mm, 1830*2440mm,2440*3660mm,etc |

Applications | Building doors and windows,Curtain walls,Skylights, Suspended ceilings,Glass floors,Skywalk,Large glass walls, Indoor glass partitions,Shop windows, Glass counters, Aquariums, etc. |

Clear laminated glass function characteristics

1)Safety,

2)Security,

3)Hurricane resistance,

4)Earthquake resistance,

5_Bulletproof,

6)Explosion-proof,

7)Noise reduction,

8)Sunlight control,

9)UV protection,

10)Water pressure resistance.

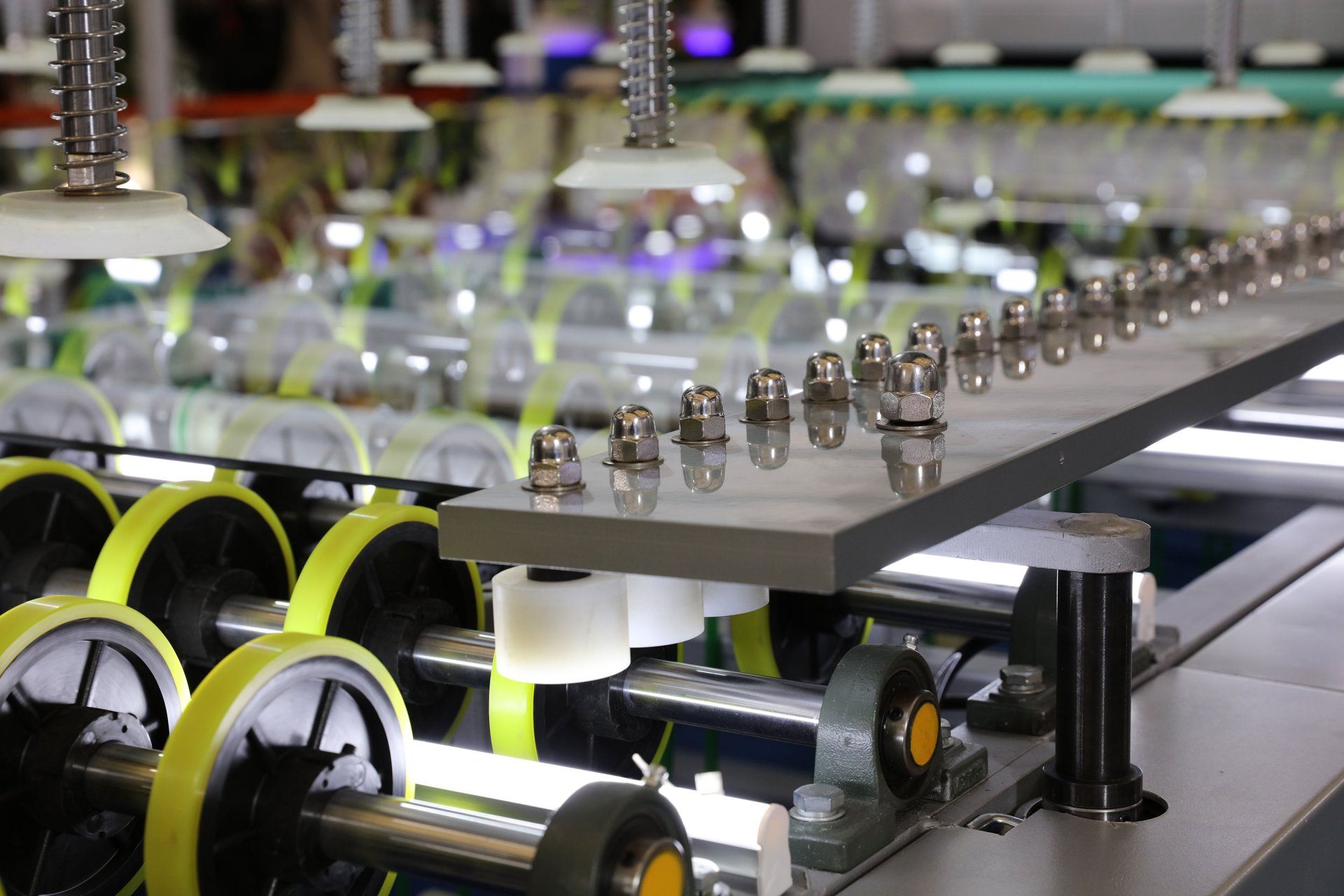

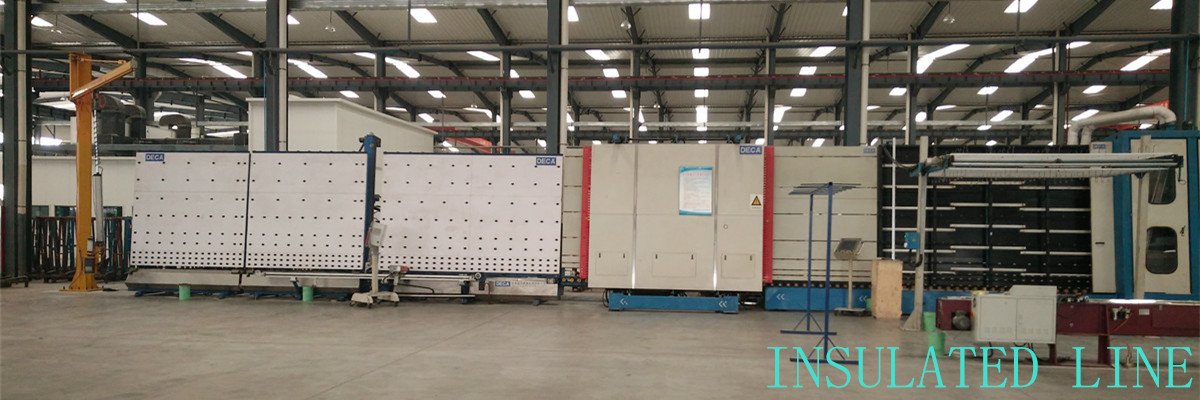

Realizable production processes

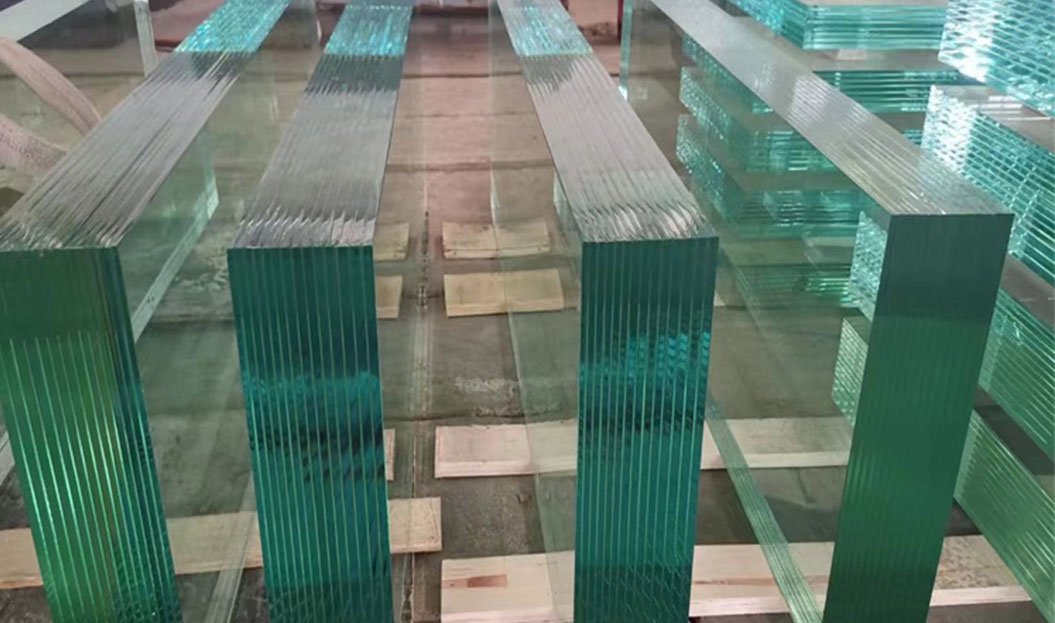

1) Precision cutting size

2) Smooth and flat edges

3) Customizable shape

4) Drilling holes are possible

5) Surface effect can be customized

6) Other requirements based on needs of every customer